28+ Blast Furnace Diagram

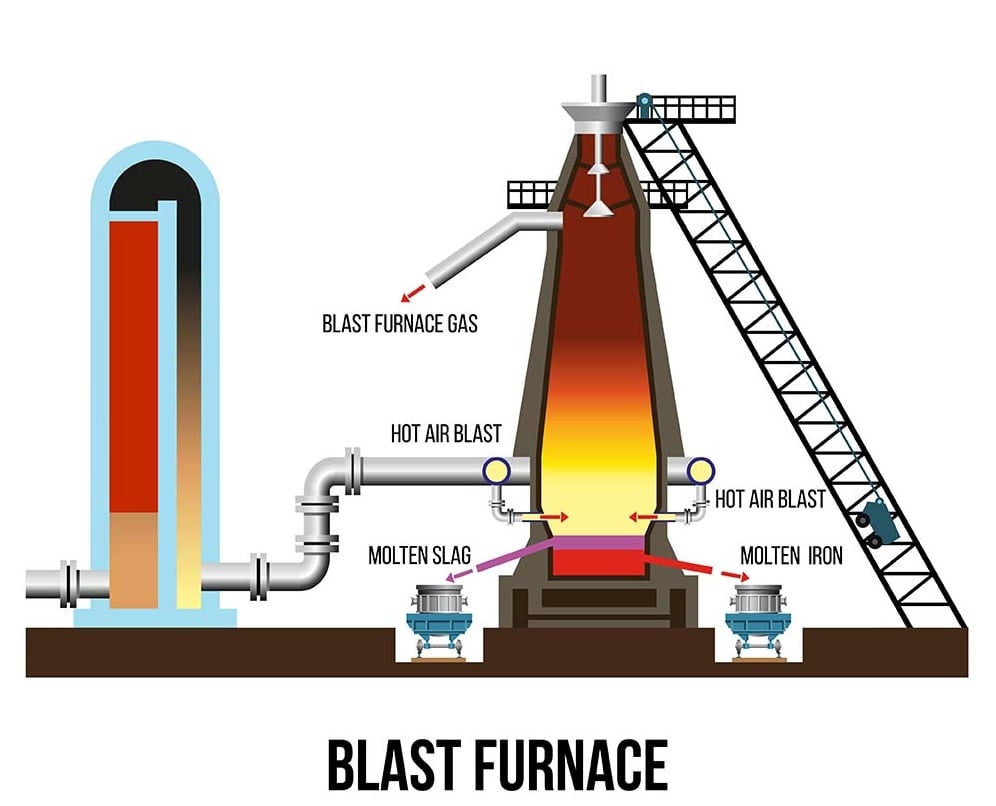

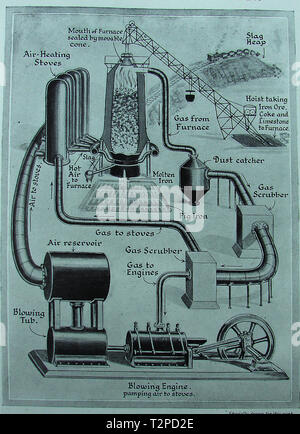

Aerodynamics in Blast Furnace-Part 3. This gas has a considerable energy value so it is burned as a fuel in the hot blast stoves which are used to preheat the air entering the blast furnace to become hot blast.

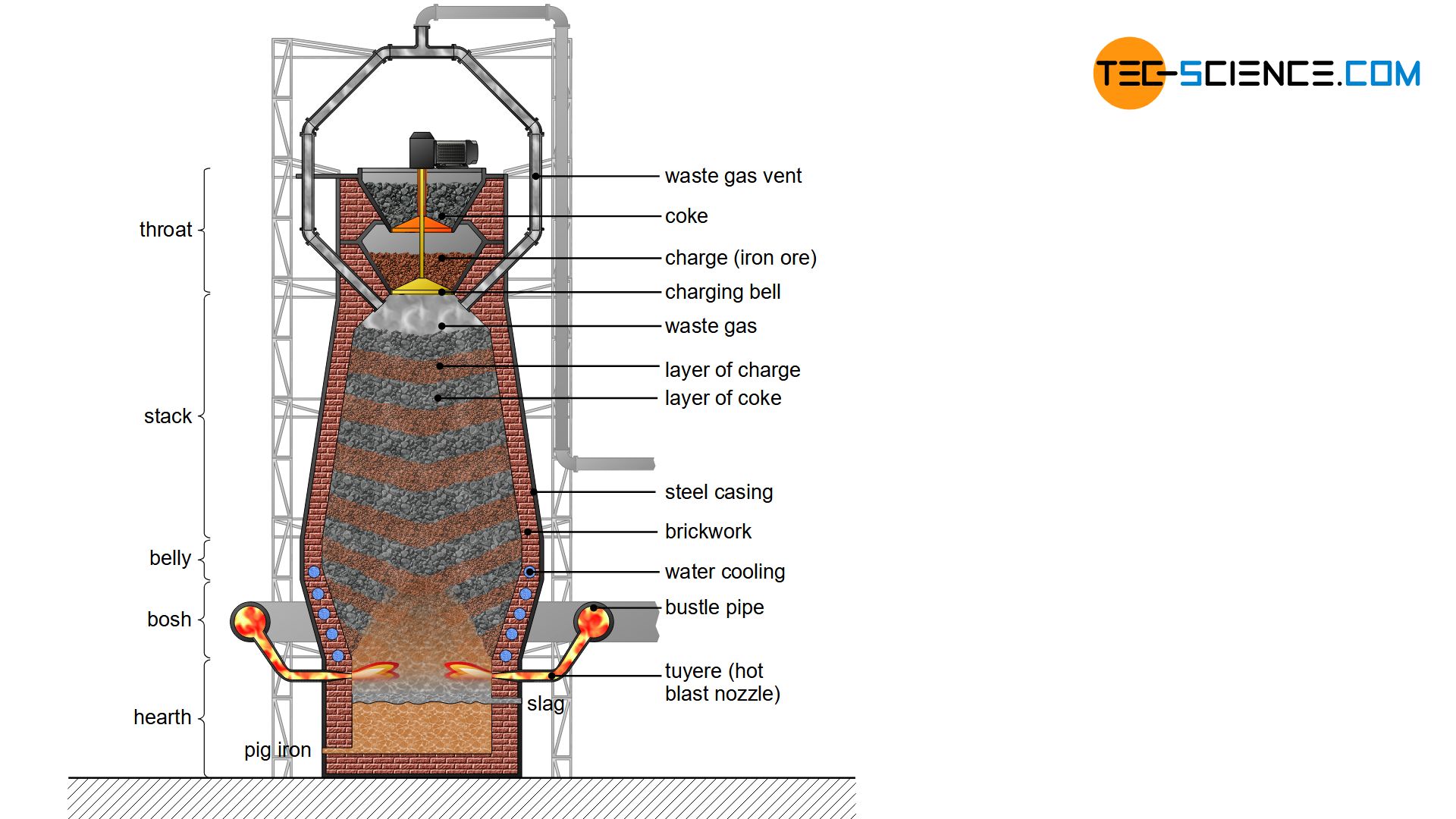

Ironworks Tec Science

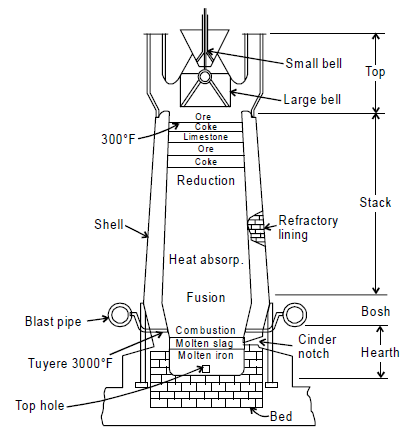

In order to operate a blast furnace stably and economically it is important to form an inverse-V shaped cohesive zone in the high Ore Coke Cohesive zone Central gas Improvement of liquid permeability in deadman Formation of cohesive zone as inverse V shape Deadman Deadman.

. Web The Blast Furnace Use the text book to help you to. Web Figure 2 a shows a schematic diagram of blast furnace interior. Coke rate and Fuel efficiency in Blast Furnace.

Feed of ore limestone and coke 7. Slags with compositions in the region of 40 SiO2 48 CaO and 12 A12O3 have low melting points ie 1300 deg C and are appropriate for the control of sulphur and silicon in. Web Home Material science Blast furnace process By tec-science - 06212018 25821 In the blast furnace the iron ore reacts with the carbon contained in the coke to form grey or white pig iron.

Web A clear simple diagram of the blast furnace for students to label. Web Fig 4 Phase diagram of CaO-Al2O3-SiO2-10 MgO system. Label the three parts shown by the labelling lines.

Aerodynamics in Blast Furnace-Part 2. Pre-heating zone throat 6. The video explains in detail the construction of blast furna.

Combustion process The iron in the processed ores must be dissolved out by chemical processes. The new model is validated with three data sets corresponding to 1 an air-blown blast furnace without auxiliary injections 2 an air-blown blast furnace with pulverized coal injection and 3 an oxygen blast furnace with top gas recycling and pulverized coal injection. The distinctive feature of this operating diagram is the graphical representation of balances of carbon oxygen and hydrogen through an operation line.

Out of that nowadays bell-less top BLT system is very popular. Web This article comprehensively discusses and elaborates the information regarding blast furnace its construction details including its main parts and their working phenomenon and function. Web The blast furnace is a tall vertical shaft furnace which uses coke to reduce iron ores.

Definition of Blast Furnace. Investigating these phenomena in a blast furnace in order to identify reserves of its efficiencyreducing coke consumption and increasing productivity. Web Schematic diagram of a modern blast furnace right and a hot-blast stove left.

The product a hot metal which is impure iron is suitable as feed material for steelmaking. Web Immediately in front of the tuyeres is the combustion zone the hottest part of the furnace 1850-2200C where coke reacts with the oxygen and steam in the blast to form carbon monoxide and hydrogen as well as heat and the iron and slag melt completely. A typical blast furnace may be up to 32 metres in height and 10 metres in diameter.

They have thick steel sides lined. Hot blast wind from Cowper stoves 2. Web EB1911 Iron and Steel - Fig.

Carefully cut out your labelled diagram and stick it into your book. Reduction zone of ferric oxide stack 5. Web A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals generally pig iron but also others such as lead or copper.

Reduction zone of ferrous oxide barrel 4. Web Inside the furnace the inserted hot blast containing oxygen reacts with the carbon in the form of coke to produce carbon monoxide and heat. Molten iron and slag collect in the furnace hearth.

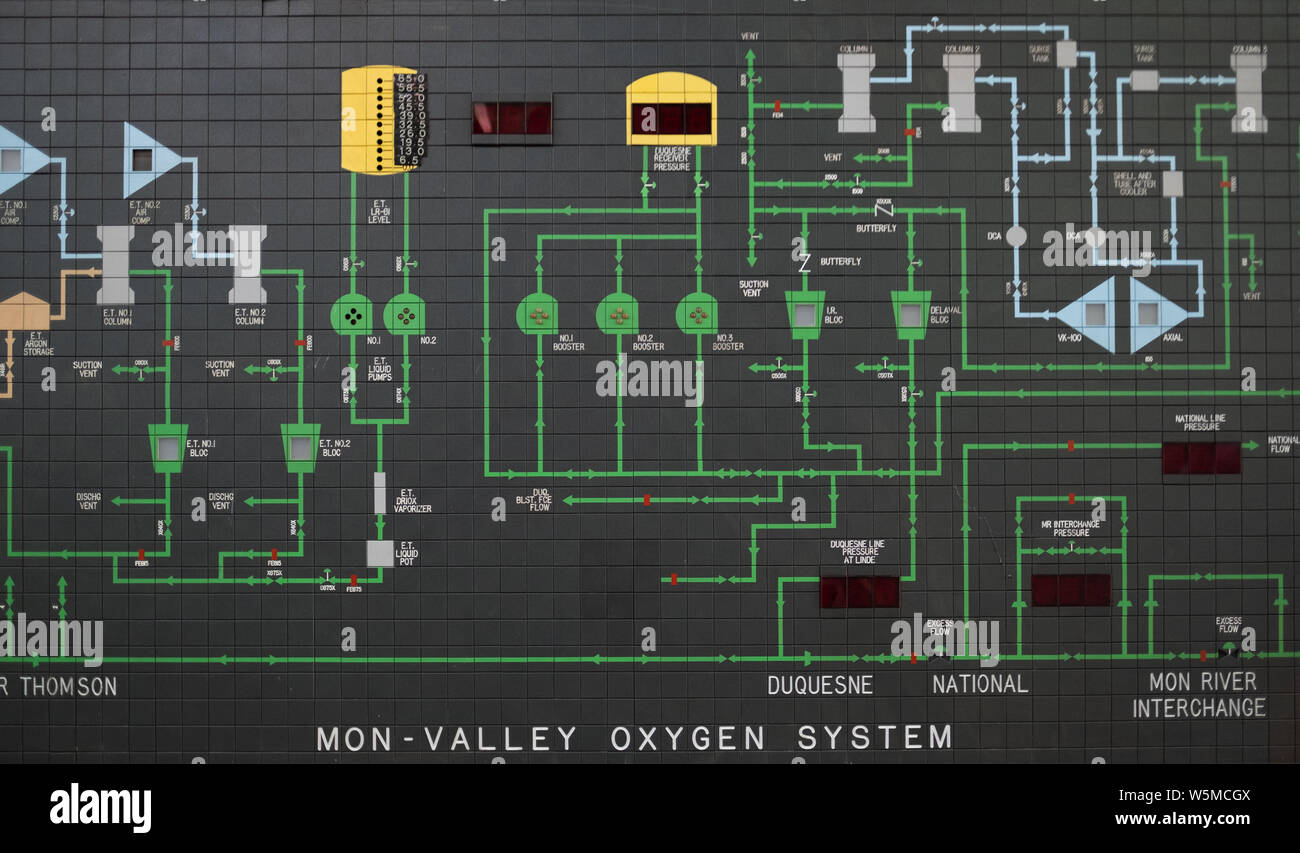

Carbon monoxide then reacts with the ferrous. The error is below 8 in all cases. 7Section of Duquesne Blast Furnacejpg 526 1340.

Web Blast furnace diagram 1. Web The blast furnace process is characterised by the variety and complexity of the phenomena of gas dynamics charge transfer heat transfer recovery softening and other phenomena. This article also highlights the application of these furnaces for its practical use.

EB1911 Iron and Steel - Fig. Web The blast furnace system is a highly complex industrial reactor in the conventional process. These gases exit the top of the blast furnace and proceed through gas cleaning equipment where particulate matter is removed from the gas and the gas is cooled.

Column of ore coke and limestone 9. Melting zone bosh 3. Label the six arrows.

Aerodynamics in Blast Furnace-Part 1. Removal of slag 10. 3 reviews Main Subject.

EB1911 Iron and Steel - Fig. Blast refers to the combustion air being supplied above atmospheric pressure. Blast furnaces produce pig iron from iron ore by the reducing action of carbon supplied as coke at a high temperature in the presence of a fluxing agent such as limestone.

Web PowerPoint Version - CLICK HERE FOR WORKSHEET A simplified diagram of a Blast Furnace is drawn below. Chemical analysis - structured questions. The temperature in the throat is 200250 C the pressure is around 15 atm there are blast furnaces in Russia and other countries that operate with bigger.

12Diagram of the Carnegie Blast-Furnace Plant at Duquesne Pajpg 900 375. Web GCSE WJEC Redox extraction of iron and transition metals Extracting iron Redox reactions are involved in the extraction of metals from their ores eg extracting iron by reduction within the. The system is subject to several problems eg system automation the thermal state of the blast.

Zone for charging the burden ferric charge reductant cokeThe blast furnace gases circulate through the throat of the furnace toward the dry and wet cleaning systems. Web Blast furnace construction and working explained in detail - Blast furnace partsdesignworking. Web It is based on plots of reduction data of a lab-scale blast furnace and was developed to a full-fledged analogue diagram in the following years.

Tapping of molten pig iron 11. Add other information that you think is important. 8Lower Part of the Blast Furnacejpg 373 399.

There is also a PowerPoint version click to reveal the labels great for a quick revsion exercise. There are different charging systems for BF discussed in detail.

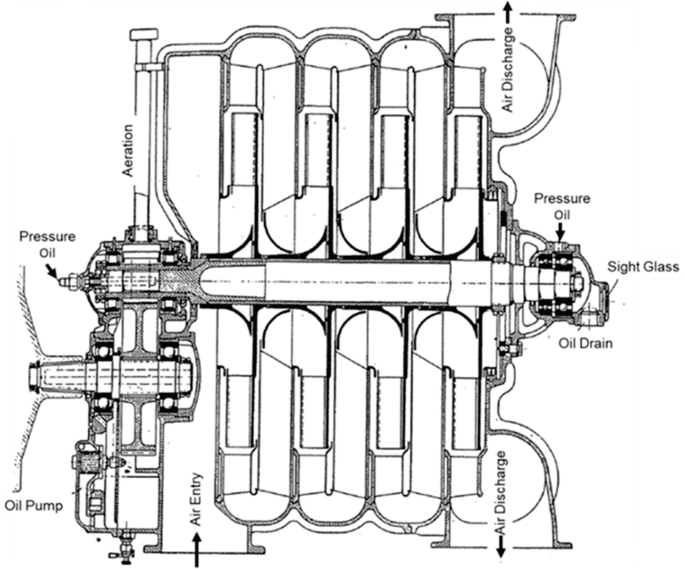

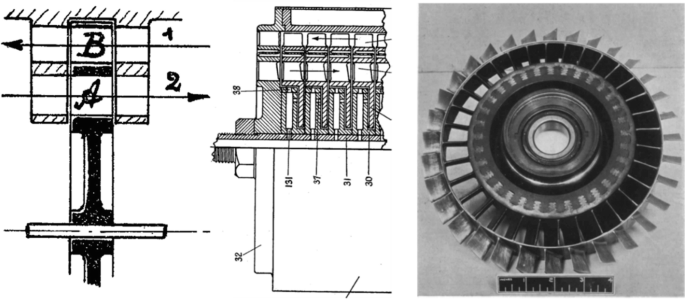

Turbomachinery And Aero Related Activities At Bbc And In International Context Up To 1935 Springerlink

Blast Furnace And Its Design Ispatguru

The Cyclone Converter Furnace Process Ccf Total Materia Article

Blast Furnace Diagram With Measurements Youtube

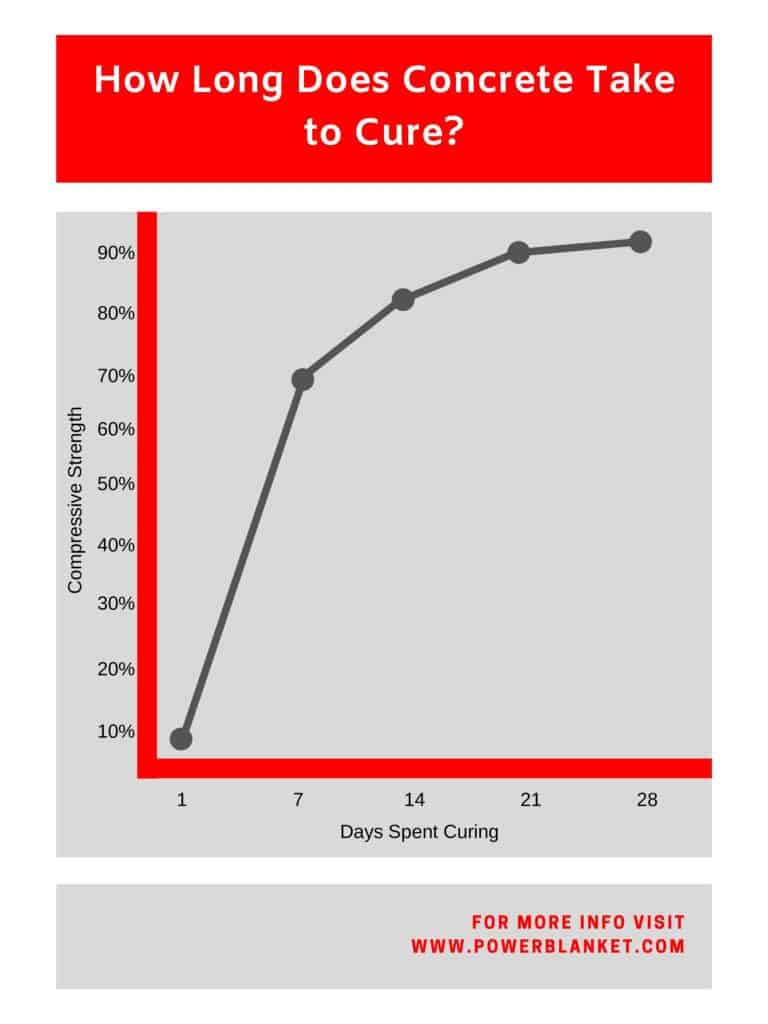

Concrete Cure Times Powerblanket Concrete Curing Experts

A Blast Furnace Diagram 1 Hot Blast From Cowper Stones 2 Hearth Download Scientific Diagram

Diagram Blast Furnace Hi Res Stock Photography And Images Alamy

Blast Furnace Explained With Diagram Blast Furnace Parts Working Applications Blastfurnace Youtube

Blast Furnace Processes Download Scientific Diagram

Diagram Blast Furnace Hi Res Stock Photography And Images Alamy

Blast Furnace Mechtech Guru

Schematic Diagram Of The Lower Part Of The Blast Furnace Download Scientific Diagram

Turbomachinery And Aero Related Activities At Bbc And In International Context Up To 1935 Springerlink

Diagram Blast Furnace Hi Res Stock Photography And Images Alamy

Schematic Diagram Of The Blast Furnace Process Download Scientific Diagram

Industrial History Blast Furnace Overview And Some General Steel Mill Videos

Turbomachinery And Aero Related Activities At Bbc And In International Context Up To 1935 Springerlink